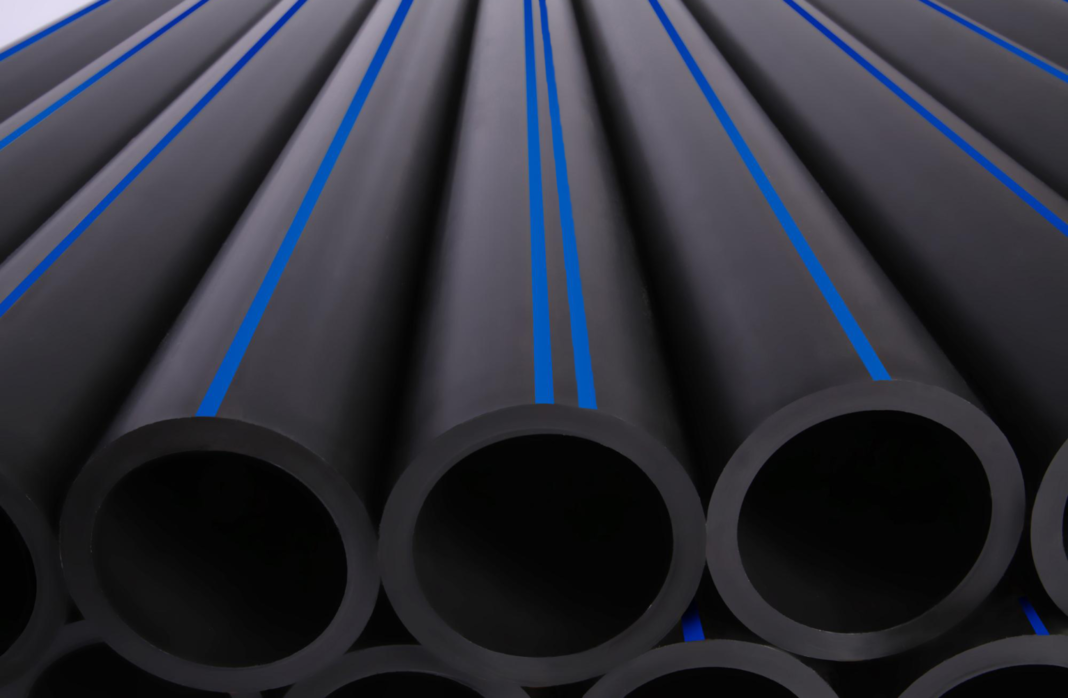

In the world of industrial applications, the choice of materials for piping systems is a critical decision. When it comes to durability, chemical resistance, and long-term performance, HDPE (High-Density Polyethylene) pipes have emerged as a prominent choice. HDPE pipes, manufactured by experienced HDPE pipe manufacturers, offer a range of advantages that make them a preferred option for various industrial uses. In this article, we will delve into the significance of HDPE pipes in industrial applications, with a focus on their chemical resistance and long-term performance.

Understanding HDPE Pipes

HDPE, short for High-Density Polyethylene, is a versatile and durable polymer known for its excellent strength-to-density ratio. These characteristics make it an ideal material for manufacturing pipes and fittings. HDPE pipes are created through a process of extrusion, which results in seamless and leak-free pipes. These pipes are employed in various applications due to their exceptional properties.

Chemical Resistance in Industrial Environments

One of the primary reasons for the popularity of HDPE pipes in industrial settings is their impressive chemical resistance. Industrial processes often involve the transportation of corrosive or abrasive materials, causing standard pipes to deteriorate under the harsh effects of these chemicals. HDPE pipes, on the other hand, have a remarkable ability to withstand a wide range of chemicals without undergoing degradation. This resistance to chemical corrosion ensures the integrity of the piping system and prevents contamination of the conveyed materials.

The key advantages of HDPE pipes’ chemical resistance in industrial applications include:

1. Protection Against Corrosion: HDPE pipes are highly resistant to corrosion, ensuring they do not deteriorate when exposed to corrosive substances. This resistance extends the lifespan of the pipes, resulting in long-term cost savings.

2. Safe Transport of Chemicals: HDPE pipes are used to transport various chemicals safely. They do not react with the chemicals they carry, which is essential to maintain the purity and safety of the transported materials.

3. Versatile Application: HDPE pipes can be used in a broad range of industrial sectors, including chemical processing, mining, petrochemicals, and more. Their versatility and resistance to various chemicals make them suitable for diverse applications.

4. Reduced Maintenance: HDPE pipes’ resistance to chemical corrosion reduces the need for frequent maintenance, inspections, and repairs. This translates into lower maintenance costs and minimal downtime.

5. Long-Term Sustainability: HDPE pipes are renowned for their long service life, even in challenging chemical environments. Their ability to withstand chemical exposure ensures long-term performance and reliability.

Long-Term Performance in Industrial Applications

The long-term performance of piping systems in industrial settings is critical. Downtime resulting from pipe failures can lead to significant financial losses and operational disruptions. HDPE pipes excel in terms of long-term performance, offering numerous advantages that ensure the reliability of industrial processes.

1. Durability and Toughness: HDPE pipes are exceptionally durable and tough. They can withstand external loads, pressure variations, and harsh environmental conditions. This toughness ensures that the pipes maintain their structural integrity over time.

2. Leak-Free Joints: The fusion welding process used to join HDPE pipes creates leak-free joints. This welding technique fuses the pipes into a monolithic system, eliminating the risk of joint failures and water leaks.

3. Resistant to Biological Growth: HDPE pipes are naturally resistant to biological growth, such as algae, fungi, and bacteria. This resistance ensures that the inside of the pipes remains clean and free from obstructions that can affect flow rates and water quality.

4. Smooth Interior Surface: The smooth interior surface of HDPE pipes minimizes friction and resistance to the flow of materials. This not only enhances the efficiency of the industrial process but also reduces energy consumption.

5. Low Friction Coefficient: HDPE pipes have a low friction coefficient, which means that they allow for efficient and smooth flow, reducing energy costs and optimizing long-term performance.

6. UV Resistance: HDPE pipes are UV-resistant, making them suitable for outdoor installations. They can endure extended exposure to sunlight without degradation, ensuring a longer lifespan even in challenging environmental conditions.

Applications of HDPE Pipes in Industrial Settings

HDPE pipes find extensive use in a wide range of industrial applications, including but not limited to:

1. Chemical Processing: HDPE pipes are used for the transport of various chemicals, acids, and alkalis. Their chemical resistance ensures safe and reliable chemical processing.

2. Mining: In the mining industry, where the transport of abrasive materials and corrosive substances is common, HDPE pipes offer a durable and reliable solution.

3. Petrochemicals: Petrochemical facilities use HDPE pipes for the conveyance of petrochemical products, including crude oil, natural gas, and various petrochemical derivatives.

4. Water Treatment: In water treatment plants, HDPE pipes are used for the transportation of treated water and chemicals, thanks to their corrosion resistance.

5 Power Generation: HDPE pipes are employed in power generation facilities for cooling water systems and as conduits for various fluids in the power generation process.

6. Agriculture: HDPE pipes are used for irrigation systems, ensuring the efficient and sustainable distribution of water in agriculture.

Selecting the Right HDPE Pipe Manufacturer

Choosing the right HDPE pipe manufacturer is crucial for ensuring the quality and reliability of the pipes in industrial applications. Here are some considerations when selecting an HDPE pipe manufacturer:

1. Reputation and Experience: Look for a manufacturer with a proven track record and years of experience in producing high-quality HDPE pipes for industrial applications.

2. Quality Assurance: Ensure that the manufacturer adheres to stringent quality control standards and certifications to guarantee the durability and performance of their pipes.

3. Custom Solutions: Opting for a manufacturer that offers customized solutions tailored to meet the unique requirements of your industrial application can be highly advantageous.

In conclusion, HDPE pipes have become a go-to choice in industrial applications due to their exceptional chemical resistance and long-term performance. The ability to withstand corrosive chemicals and provide reliable, leak-free performance over time makes HDPE pipes an essential component of many industrial processes. When selecting an HDPE pipe manufacturer, prioritize reputation, experience, and a commitment to quality to ensure the success of your industrial projects.