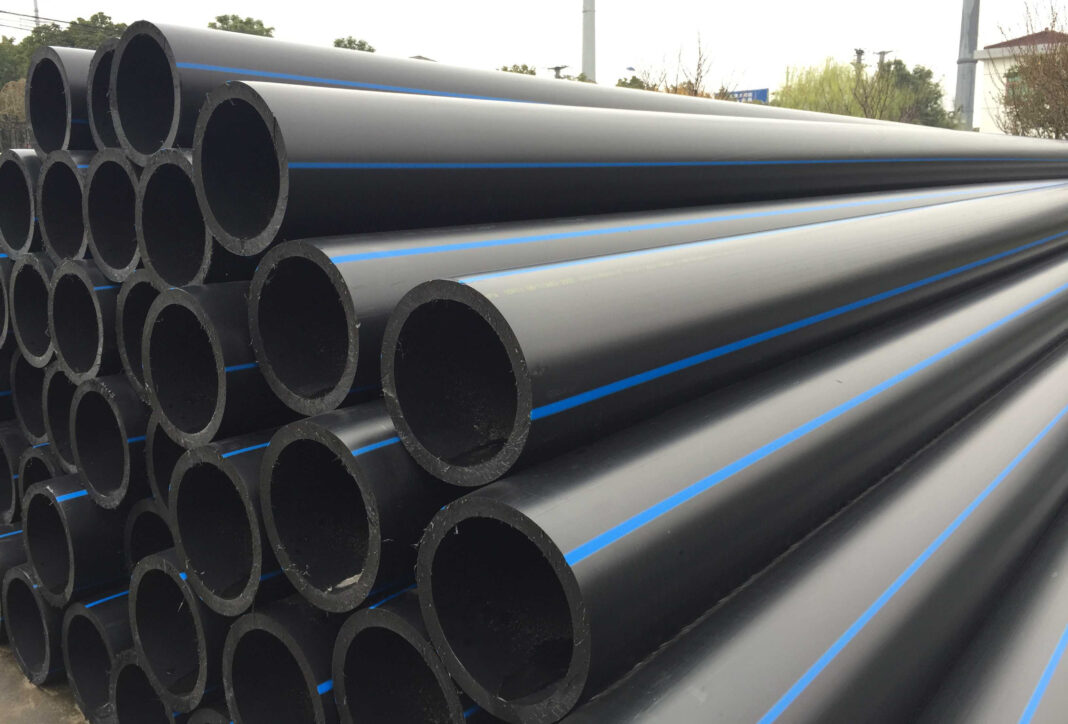

HDPE is an acronym for High-Density Polyethylene. It is the commonly used piping systems fund application in water and gas transport. Another interesting application lies in earth energy or geothermal applications.

What is HDPE?

These are flexible piping systems manufactured from thermoplastic. It is further made of polymer resin. Comprising numerous properties, they impart impermeability and durability, among a few. Read on to learn more about HDPE pipes.

How are they different from PE pipes?

PE represents polyethylene. As evident by the name, HDPE is a type of PE pipe. The PE pipes come in multiple densities such as very low, medium, and low-density. Also, there are cross-linked, ultra-low, high, and high molecular weight, low linear density, and chlorinated pipes. They are denser and less flexible than generally available PE pipes. They may also have carbon black added during the manufacturing process. However, the procedure varies among industries.

The addition of carbon black layering provides UV resistance to the pipes, making them safe for outdoor and direct sun rays. These pipes are more durable and can withstand higher temperatures, impact, and chemicals. They have high melting points, toughness, and resistance to chemicals and corrosion. The efficient properties are coupled with less weight.

They are also superior to PR pipes considering their rust resistance. Moreover, they also trigger internal pressure resistance, and the flow capacity remains unhindered regardless of environmental factors. It decreases the requirement for maintenance.

How many types of HDPE pipelines are available?

The HDPE pipelines can be single-walled, double-walled, or spiral polyethylene pipes. The categorisation is based on the type of walls of polyethylene pipes. Single-walled polyethylene pipes are suitable for a pressure range of two to forty bards. The double-wall polyethylene pipes have an outer corrugated layer and an inner smoother layer. It gives them the name corrugated polyethylene piping. The outer layer imparts resistance to pressure and impact and provides flexibility.

Spiral polyethylene pipes are better than double-wall polyethylene pipes. The spiral nature of the outer wall makes them slightly more resistant to higher pressures.

HDPE pipelines are also classified according to transporting items and density. They are of two types, HDPE 80 and HDPE 100.

HDPE 80 pipes are for gaseous transportation, and HDPE 100 deals with fluid materials. The latter is manufactured at higher density and has thinner walls for stability. The higher strength ratio also keeps them operational under high temperatures and provides resistance against sunlight.

Characteristics of HDPE

- Leak-free joints: HDPE pipelines and fittings are joined through different types of welding. Butt, socket or extrusion, and electrofusion welding impart strength. Also, they ensure the formation of leakage-free joints.

- Installation: HDPE provides hassle-free installation compared to PE pipes. Their installation is through environment-friendly and trenchless technology. Using the open-cut method, they can be effortlessly installed under rivers, roads, creeks, and lakes with minimal environmental effect.

- Environmental impact: The environmental impact is lesser compared to PE pipes. Lightweight eases their transport and makes them sustainable due to the requirement of low investment. Moreover, welding eliminates the need for specific diameter fittings, declining waste generation. They also do not emit toxins being transported, thus protecting the environment from any damage.

Uses of HDPE

HDPE pipelines find usage in different systems:

- Utility transport like gas, water, and electrical conduit

- Sewer, sanitary, and iron or tin ore slurry transfer

- Fumes extraction

- High-pressure pipelines

- Boiler ash handling, cement or clinker handling, coal

- Telecommunications

- Marine outfalls, pipeline effluent, and saltwater intake lines

- Air conditioning and refrigeration

- Stormwater and drainage pipes

- Drip, sprinkler, and flood irrigation in agricultural systems

- Petrochemical and fertiliser industry

- Ground loops

- Radioactive and hazardous wastes

Advantages of HDPE

Here are some of the key benefits of HDPE pipes that everyone should know.

- They tend to be cheaper when compared to the other piping techniques.

- Provide resistance to freeze damage, corrosion, deposits, and tuberculation.

- The fittings and joints of the HDPE are flameless and eco-friendly.

- Less labor is required as they are light-weighted compared to concrete, steel, and other materials.

- Durable and long-term reliability provides help in longevity and one-time investment.

- Suitable for potable water and drinkable fluids due to preservation of the quality.

Disadvantages of HDPE

- They offer low strength or stiffness.

- They are flammable and vulnerable to cracking under stress.

- The effect of weather decreases their applicability.

- The poor high-temperature conduction further decreases their usage.

- These pipes are not biodegradable.

- They do not provide resistance against oxidising acids and chlorinated hydrocarbons.

Conclusion

HDPE or High-Density Polyethylene pipes hold unique properties and capability for wide applications. The same is evident from usage in different domains. Capable of withstanding high temperature and pressure, HDPE pipes are cost-effective and environment-friendly, along with high impact resistance. However, they are associated with certain disadvantages. The latter should be kept in mind before investing in, or choosing the PVC plumbing pipe.