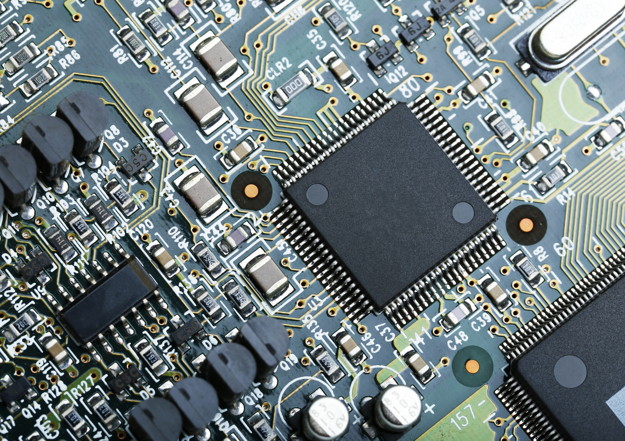

PCB assembly or PCBA is a process of assembling PCBs (printed circuit boards) using appropriate techniques and equipment. This is done by using automated processes to assemble the components on the board. Assembly is the process of putting together the components of an electronic device.

The process of PCB assembly can be complex process but with a reputed company, it would be simplified. A good company will incorporate all the necessary steps into its streamlined and user-friendly online ordering system, making your printed circuit board assembly order very easy!

All you need to do is upload your files, go through their quick online quote and then send them your order.

What are the PCBA steps in a nutshell?

Step 1: Design and layout

Step 2: Assemble the PCB

Step 3: Solder the components

Step 4: Finish, test, and assemble the board

What are the two most used PCB assembly techniques in the market?

1. Through-hole Technology (THT)

Through-hole PCB assembly technique is a method of connecting components to the PCB through holes. The following are the steps involved in this type of assembly:

Step 1: The through-hole PCB is manufactured by printing a design on a copper board and then cutting it out.

Step 2: A drill bit is used to drill holes in the copper board at each location where components will be placed.

Step 3: The components are mounted on small pins or balls, which are inserted into these holes.

Step 4: Solder paste is applied over all components, followed by soldering all pins together using an iron.

2. Surface Mount Technology (SMT)

A surface mount PCB assembly technique is used to assemble a printed circuit board in a very precise way. It is known as a solder mask, and it is created by applying a layer of solder on the board and then applying another layer later on.

The first layer of the mask is made up of tinned copper, which acts as an electrically insulating material that protects the components from short circuits caused by other parts.

The second layer of the mask is made up of a tinned polyester resin, which serves as a conductive material that allows current to flow through it.

After both layers have been applied, they are heated together until they fuse together.

The surface mount technique also enables you to build larger electronic devices with fewer components, which saves space and manufacturing costs.

How to choose an assembly company?

There are a lot of reasons to choose the right company. The first reason is that you can choose a company that specializes in manufacturing PCBs and has the necessary experience.

When choosing the right PCBA company. It is necessary to understand the characteristics of your product and then choose a specific manufacturer according to these characteristics. For example, if your product requires high-quality components, then it is very important for you to choose a manufacturer that specializes in manufacturing high-quality components. In addition, if your product requires advanced technology (such as chip design). Then it is also important for you to choose a manufacturer that has advanced technology.

Last but not the least, consider the pricing.