Created from austenitic stainless-steel for included toughness and greatest resistance to corrosion, Securistyle‘s prime-promoting merchandise assortment has just lately been redesigned and enhanced.

Page metal is actually only the perforated sheet metal aimed right into a custom metal stampings Ironing – the material is squeezed and lessened in thickness alongside a vertical wall. Utilized for beverage cans and ammunition cartridge cases.

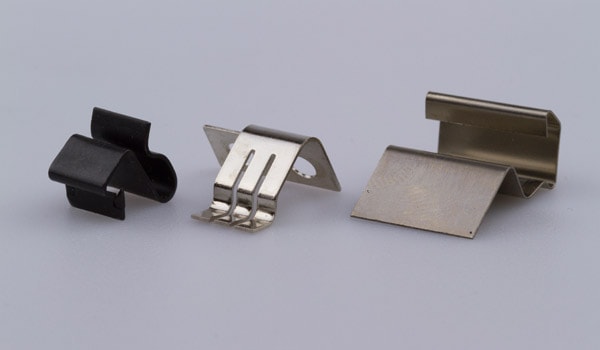

We can fabrication and custom metal stamping parts manufacturer Precision metal stamping Malaysia streamlines the entire process of metal stamping by automation of your metal conversion course of action. In precision metal stamping, the measurements of the final products tend to be more correct and specific than every other stamping system.

Accurate metal factor manufacturing provides us along with several items, but most of us don’t know just what precision steel element production in truth indicates. The particular goals of this short article in an effort to particularize the tactic describe the various procedures to component production and supply kinds of goods manufactured outside of precise metal component generating.

From coining and deep drawing to progressive die and robotic stamping, LCS Corporation takes advantage of differing kinds of generation strategies to fabricate custom metal stampings. Depending upon the manufacturing needs, operations are preferred to make prototypes and agreement production volumes.

At the time Now we have your approval to start out producing your stampings, regardless of whether your parts demand large or small precision, we use fully automated robotic strains and progressive die output to be sure precision even though beginning in essentially the most economical mass output method. We use tooling and tooling sets that assure our stamping tolerances are in 0.0005.

Metallic stamping die would be the gizmos utilized in metallic stamping equipment. Each and every metal rubber stamping equipment can have quite a few as compared to one particular stamping die according to the type of unit.

Getting opened a plant (that has a mirror transfer press line for set-best bins) in 2006 at Nitra from the Slovak Republic, we are well positioned to deliver local creation remedies to big electronics corporations as well as their network of producing companions within the area, starting from Panasonic, Hitachi and Philips to Celestica, Elcoteq and Flextronics.

Features a die black mounted with a punch plate with perforators from the upper die. Allows the cutting of inside and exterior element capabilities on a single operation

An array of framing operations arriving underneath the starter of foldable and twisting are executed on presses together with very similar devices, in conjunction with this kind of functions for the reason that rubber stamping, crimping, beading, seaming along with grooving and so on These types of procedures provide the actual shaping or even stiffening connected to metal linens, the actual forming connected with tubular parts of round or Various other condition and lots of Several other motives.

The most important reason that hot parts happens to get essentially the most sought-soon after approach is always that it offers the likelihood for real-time control of multifaceted microstructrures in thermomechanical processing.

Various diverse output options is usually executed based upon part geometry and specifications. The underneath terms describe several of the more widespread attributes located in stamping apps as well as their purpose.

Offered acceptable design of a bearing assembly, a effectively chosen Belmont Babbitt alloy will give effective assistance beneath lots of situations

Sensors including eyesight devices with inline device sensors are also accessible to inspect formed precision metal stampings in order to determine defects and stop parts out of tolerance.